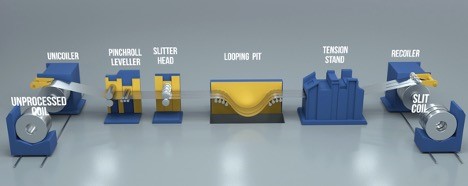

Steel slitting is a steel manufacturing process wherein a coil of steel is slit into the lengths and widths specified by the end application. This process requires machinery lines equipped with a decoiler, slitter, and a recoiler — to achieve the end product: slit steel coils, or “mults.”

An operator will feed the steel coil onto the uncoiler mandrel. The uncoiler unwinds the master coil, feeding it into the slitter head where the steel will be slit into narrow mults (strips) by rotary knives. The operator then inspects the individual mults to ensure the gauge width and edge condition meet required specifications. The mults will then travel through a looping pit to insure stress-free and camber-free recoiling of the slit material. Individual mults are then banded and packaged to specific customer requirements.

| – Welded Steel Body |

| – Sensitively processes body and cylinders |

| – Suitable thermal process and sanding operations |

| – Sensitive assembly workmanship |

| – On-demand custom design – project and manufacturing |

| – 0.30 – 10.0 mm metal sheet thickness |

| – 400 – 2000 mm metal sheet width |